Breathe joined forces with Four Pillars Gin to create a new, immersive gin experience in their birthplace, Healesville.

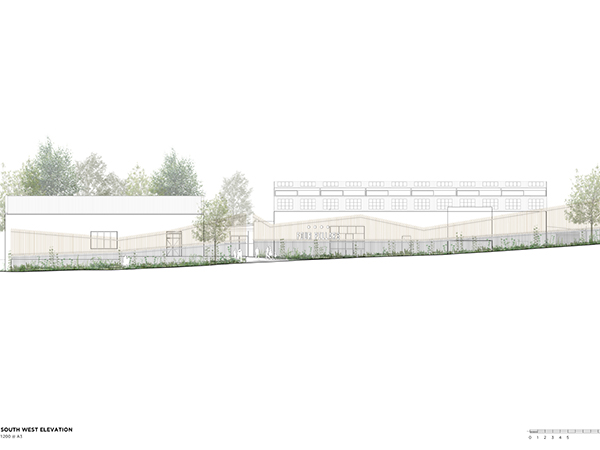

The project is surrounded by mountains, temperate rainforest, oaks, and elms and throughout the design we acknowledge Four Pillars’ origin, their history, and their deep connection to the place where it all began.

The project nearly triples the capacity for visitors, as the expansion delivers a much-needed new production space, an outdoor gin garden, tuckshop, dedicated gin shop, a custom-built bar, and events space cementing Four Pillars as the largest gin-focused distillery in Australia.

Importantly, this project will see Four Pillars continue their commitment to sustainability and community with the implementation of new sustainability initiatives and the creation of countless local jobs. The design helped Four Pillars become Australia’s first carbon-neutral gin business.

It is 100 per cent fossil fuel-free, sustainability is embedded, from the copper veil, the 100-kW solar rooftop, the recycled masonry throughout to a restrained and crafted natural material palette.

Ongoing waste minimisation was important to the project and all steel, concrete, and timber waste was recycled during construction and no excavation was sent to landfill. Gin is piped directly into the main bar from production through featured copper pipes that will see the site save 29 tonnes of glass per year.

List all the sustainable products used in this build:

- 100% fossil fuel free, powered by a mix of solar and 100% certified Green Power

- 100KW solar with plans to increase this further in the future to maximise solar power generation

- Commercial kitchen is 100% electric, no gas

- Roof material selected for maximum solar reflection

- Captured rainwater for irrigation and toilet flushing

- Landscaping - local, native or food producing plants

- Material reductionism - removal of unnecessary coatings and finishes from interiors

- For example, raw copper & steel joinery, polished structural floor slab, exposed steel structure & precast walls, natural coir matting, natural recycled brick, raw copper tapware, exposed services

- Gin is piped directly into the main bar from production through featured copper pipes to reduce glass waste

- It is expected that this will reduce glass recycling by 10 tonnes per year

- Tonic taps - moved from bottled tonic to tonic in kegs which is expected to reduce glass waste by up to 19 tonnes per year

- All steel, concrete and timber waste was recycled during construction

- No excavation went to landfill

- Robust natural and raw materials throughout designed to wear well & have ability to be recycled at end-of-life Low VOC paint & sealer finishes Envirocrete - by Boral - approx. 40% reduction in cementitious content and silica, 25% manufactured sand content (manufactured sand is also a by-product) and 50% recycled water content

- Australian hardwood timbers

- Recycled bricks and brick tiles

- A copper pipe veil encloses the site

- A section serves the function of pre-cooling the still condenser water as it is pumped through the copper pipes before it goes into coolers

- Raw Galvanised steel

- Locally made steel windows Pinatex upholstery - natural fabric made from pineapple leaf fibre

- Ambience lighting with recycled content Australian-made furniture by local designers Jude’s Gin Garden is an exterior roofed Australian hardwood deck featuring plants that can be distilled

Furniture: Dowel Jones, Life Space Joinery, Design by Them

Lighting: Ambience, Rich Brilliant Willing. Finishes: Insitu, Pinatex

Fittings & Fixtures: Never Stop Group.

Sponsored by Network Architectural

+Category+Winner%3a+Four+Pillars+Gin+Distillery+2.0+%7c+Bre+%7c+Architecture+%26+Design&pu=/projects/hotels-hospitality/2022-sustainability-awards-commercial-large-catego&pt=_Project)

+Category+Winner%3a+Four+Pillars+Gin+Distillery+2.0+%7c+Bre+%7c+Architecture+%26+Design&pu=/projects/hotels-hospitality/2022-sustainability-awards-commercial-large-catego&pt=_Project)