We’ve got smart phones, smart TVs and now, smart meters.

Smart meters have the potential to change the way consumers look at, and use their energy, allowing them to be conscious of their usage patterns. They are meters with data logging and communications which record and transmit a building’s energy usage. Typically, a smart meter will read and store energy usage every 30 minutes and then send this information to energy distributers, or users.

Smart meters have come a long way. Traditional meters, or accumulation meters would simply record the amount of electricity which passed through it since it was first installed, or was last reset. The shortcomings of this style of meter was users would only find out their energy usage when they received their bill and a large amount of labour was required by the provider to send a reader from house to house in intervals to read the meters.

Accumulation meters progressed to interval meters, which measure energy electronically. They can record usage in intervals, usually have a digital display and the data can be downloaded by a reader using an electronic or optical interface. They enable a customer to pay different rates for different time periods in which they use their electricity. However, they are not considered smart meters.

SMART METERS SAVE SPACE

A smart meter is “smart” due to its ability to record more accurate and detailed data and facilitate a two-way flow of information. They eliminate the need for meter readers to visit each meter. Smart meters can receive commands from the supplier and carry out tasks such as disconnecting and reconnecting the power supply when a customer moves out or in. It continuously monitors the supply and can automatically notify the provider if there is a fault. They can also act as a gateway to the home for information.

The space-to-design ratio performance of smart meters has improved as technology advances. Less panel space and electrical installations are required and advanced smart metering designs can use up to 90 per cent less space when compared with typical ‘bottom up connect’ utility meters. This is particularly valuable in high-density, high-rise buildings.

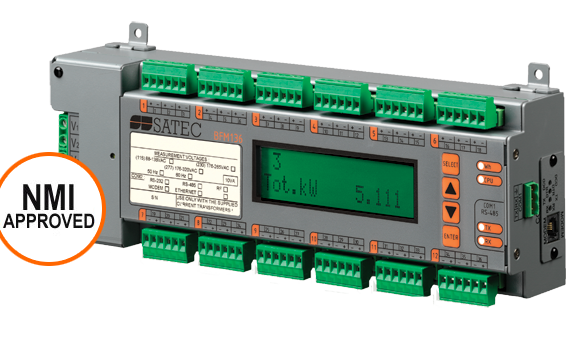

Satec’s Branch Feeder Monitor BFM136 automatically provides metering, demand and energy readings, logging and multi-tariff (TOU) data. It monitors up to 12 three phase circuits or 36 single phase circuits, or any combination of single or three phase circuits, making it suitable for multi-tenant facilities such as residential projects, office buildings and shopping malls.

HOW ARE THEY USED?

With any data-driven technology, it’s not the data which drives innovation, but the way in which it is used.

“Smart meters can create structures internally that allows a consumer to understand their usage patterns,” explains Dean Davis, Director of Satec, an energy management solutions company.

“This is done by recording information, and having a clock on-board the meter. Thus, now the information logged to memory can detail what time energy is consumed.”

Timing of energy consumption is used by retailers to offer Time of Use (TOU) tariffs, which reward people for using electricity outside of ‘peak’ periods.

Furthermore, consumers can use this data to identify what time they use more energy. They can be programmed to provide feedback on their consumption and automatically send messages based on instructions. For example, a user can opt to be notified if their energy usage is unusually or undesirably high.

Smart meters make it easier to identify sources of high energy use and can prompt users to modify their behaviour. This may lead to energy-saving decisions such as taking shorter showers, or opting for more energy efficient appliances.

This can be communicated to the user via an In Home Display (IHD). A simple IHD indicates which price-period (according to the TOU tariff) a user is in, while a more complex IHD displays the total power the house is using. This allows a user to watch their usage change depending on which appliances they are using and identify which appliances to avoid during peak periods. A more advanced IHD may show the cost of the energy used at low, medium and high price periods over a time frame and allow comparison on prior corresponding periods. Customers may also choose to be notified if there is a high availability of green power, so they can use energy when the greenhouse gas intensity of the supply is low.

When integrated into a smart grid - which combines advanced communication, sensing and metering infrastructure with the existing electricity network - smart meters have significantly more benefits. Smart meters can help create a system which automatically uses power in an eco-friendly and cost effective way.

Smart meters can facilitate smart appliances, which are capable of adjusting their operations to information it receives, in a way that is helpful to the user or the grid. This may involve turning off for a brief period or operating in low periods instead of high. It may opt to use green energy when there is high supply of it, or discharge stored energy to the grid when it is needed. This functionality is a step beyond what a IHD can provide in that the user does not have to be home to manually react to an event when it happens. The appliance will respond automatically to pre-programmed events, unless instructed otherwise, so the user can simply “set and forget”. This can contribute to a green rating.

WHERE ARE WE NOW?

The usage of smart meters varies throughout Australia and different states and electricity suppliers have different policies. Some have committed to replacing old meters over a predetermined time frame, some are installing smart meters only in new buildings or when the old meters need replacing and others are continuing to install interval meters. Furthermore, just because a smart meter is installed, doesn’t mean its capabilities are being utilised.

Not everyone has warmed up to smart meters. In 2006 the Victorian government mandated the roll out of smart meters. Every Victorian household was required to pay for a meter and all needed to have the same type, whether it suited their needs or not. Take up of TOU tariffs was low, meaning the largest benefactor of the rollout was the supplier, as they no longer had to send an energy reader. Furthermore, despite the consumer paying for the meter, it was owned by the supplier. In Victoria, the roll out of smart meters is effectively complete and they will continue to be the standard in the state.

Manufacturers of smart meters were the big winners from the Victorian Government’s 2009 smart meter rollout. Image: Grey Ink

CONCERNS: BIG BROTHER, MICROWAVES & ACCURACY

Resistance to smart meters revolves around three concerns: privacy, safety, accuracy.

Similar to the “big brother” argument, Davis says some people believe “privacy could be compromised by learning one’s habits as a smart-meter can tell what times during the day you use resources.” Davis says this can be resolved by using encryption and improving policies governing the use of modern communication techniques.

Some have expressed safety concerns regarding smart meters use of Radio Frequency. Emissions from radio frequency is a widely debated issue, which stretches into the use of microwaves, mobile phones and Wi-Fi. Smart meters use technology commonly used in other areas and all are required to comply with Australian safety standards. They use communications such as Zigbee (similar to Bluetooth), 3/4G using cellular SIM cards and metropolitan based RF communication systems in ranges of 900MHZ and more. The debate is not exclusive to smart meters, but Davis says one way to fix the issue is to use hard wired cables such as CAT-6 cabling, like the NBN uses. “Smart meters can use modern Ethernet TCP/IP communications to connect directly to Ethernet, and this would eliminate any Radio Frequency issues as they connect easily to a consumer’s home modem/router,” he explains.

There are some concerns regarding the accuracy of some smart meters. Naturally, consumers want to know the information they are basing their behaviour around is accurate. The accuracy of a meter is dependent on factors such as the load of the network and the power factor of the system. Some low-cost solutions have issued with electronics such as ‘harmonics’ caused by many small transformers used for phone chargers, air-conditioning inverters, etc. Due to improvements in electronics, smart meters are more accurate than before. IEC/AS have developed standards known as “Accuracy Class” to define accuracy under different load conditions. Check the accuracy class complies with the desired functionality.

WHERE TO GET THEM

Architects can have a discussion with electrical contractors or engage directly with suppliers to evaluate the technology and discuss ways in which a smart meter can improve the design of the building.

TWO CASE STUDIES

Case Study: One Central Park, Sydney

One Central Park by Ateliers Jean Nouvel and PTW Architects. Photography by John Gollings

One Central Park is not easily missed on the Sydney landscape. But there’s a lot more than meets the eye to this building. It was developed with the hefty goal of building Australia’s greenest and most self-sufficient mixed-use urban development. Built around more than 6,400sqm of parks and public spaces, the two towers redefine green living – both inside and out.

One Central Park has a billing grade Energy Management System (EMS) supplied by Siemens in over 1,400 apartments. The system created is rather complicated, but also brilliant.

The building and energy management system includes 1,663 smart meters which monitor the apartments, retail shops, bulk water meters and the electrical switchboards. There are 3,000 hot/cold and bulk water meters, 1,428 touch screens in the apartments, 42 M-bus thermal energy meters and 70 BACnet/IP programmable controllers integrated to the smart meters, touch screens and thermal meters. In addition, there are 26 Virtual Local Area Networks, 26 BACnet Broadcast Management Devices, a layer 3 switch on a third party network and a server with remote access. This system generates 148 daily energy reports.

“It means we can email daily energy and water consumption reports for all services to the customer for billing purposes,” says Siemens Executive General Manager Building Technologies, Stefan Schwab.

“At the touch of a screen located in each apartment, residents can monitor apartment total energy, and hot and cold water consumption.”

Using these touch screens, residents can see their energy and water consumption in real time, along with the indicative cost and greenhouse gas emissions.

“This means tenants can monitor their instantaneous energy consumption, cost and CO2 emissions and compare with previous days, weeks or even months, allowing them to track and alter their usage prior to receiving a bill,” Schwab says.

In addition, Schwab says the EMS can scrutinise chilled water, hot water, domestic hot water and spa thermal energy meters, monitor main switch board electrical meters and inspect bulk potable and non-potable water meters. All of the EMS functions use fibre-optic infrastructure.

Schwab says the main risk of the project was to provide a robust and reliable billing grade EMS that met all standards and requirements.

“Our team worked closely with the developers to produce an energy meter customised specifically to the requirements of One Central Park,” he says.

Case Study: ALDI Distribution Centre, Jandakot

Designed by Oakfield, The Jandakot WA Aldi foods distribution centre recently received a 4 Star Green Star Rating Industrial Design V1 from the Green Building Council of Australia. Image: Georgiou Group

ALDI's first step in establishing a Western Australian presence was to commission the construction of a $60 million, 45,000sqm facility located within the Jandakot Airport industrial precinct. Wood & Grieve Engineers (WGE) were engaged by Georgiou Group to provide full electrical, hydraulic and sustainability design services, as well as peer review roles for fire, civil and mechanical services.

The ALDI Distribution Centre utilised a Frako power monitoring and maximum demand controller system, which included a network of 37 smart meters. The system consisted of a headend computer, modems for connection to the Frako network, a RS232 communication network linking all devices, expansion modules for load shedding, a Frako maximum demand controller and connections to the site wide metering system.

Frako units like this EM-MC 2200 are marketed to small to medium-sized industrial and commercial operations, office buildings and hotels. Frako says the product is an investment with a short payback time even in the deregulated energy market, since exceeding the specified power peak limit still results in extra costs that can be avoided.

“ALDI are a quite advanced in their distribution centre design - they’ve built these all over the world, so they are quite aware of smart metering and smart grid technology,” explains Elliot Alfirevich Electrical Project Engineer, Wood & Grieve Engineers.

Elliot Alfirevich says the system is “quite clever” as it included a “maximum demand optimisation computer”, which calculates the power demand at the site and shuts down mechanical services or the refrigeration plant at key times to reduce the electrical demand.

“This can be configured to save energy during peak billing periods, but in our case it’s used when the site runs on generator. Controlling the start-up of the mechanical/refrigeration plant while the site is on generator reduces the demand on the generator and avoids generator overloads,” Alfirevich says.

Six levels of load shedding were configured to ensure that loads are switched in a staged manner and the operational impacts of each load shedding level has been considered by the client. For example, management procedures exist to manage staff expectations when the lunch room air conditioning may be unavailable and to manage the limitations on the building during a load shedding sequence.