Clean air, a stable electricity grid, and reduced greenhouse gas emissions are critically important to society – all features of sustainable evaporative cooling that leverages nature’s most powerful, renewable refrigerant to cool people with less than half the water of last century’s technology.

Despite its technology advancements, evaporative cooling is under increasing pressure, and in some cases outright prohibited in arid regions where it is most effective, because of the misconception that it wastes a precious resource – water.

Firstly, let us explore water quality, before understanding how it affects evaporative coolers and the management of water in today’s technologies.

Not all water is created equal. Hard Vs Soft water: What’s the difference?

Hard water is defined as having a higher mineral content of calcium and magnesium. Soft water, such as rain, has a much lower mineral content. Knowing where your water lands on the scale becomes especially important when analysing the impact it has on the lifespan of water-using appliances and their maintenance requirements.

Why does this matter for evaporative coolers?

Evaporating six litres of water generates over a ton (3.5kW) of cooling effect, but will leave behind any minerals that were present in the water. If those minerals are ‘hard’, like calcium and magnesium, they will bond to the evaporation surface, degrading cooling performance and eventually stopping the system from functioning at all. The ‘harder’ the water, the quicker the buildup of minerals. Draining water before hard minerals fall out of solution, therefore, serves the engineering purpose of protecting the client’s investment in a high performing, long-serving HVAC system.

How drainage water management has changed over time.

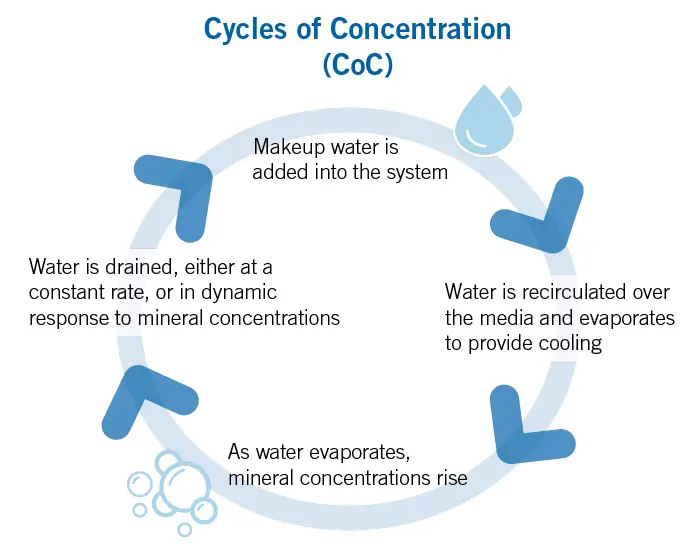

Historically with older technologies, this function is provided as a constant bleed or volume dump, with the drain water rate providing a set ‘Cycles of Concentration’, or CoC, designed to avoid mineral fouling at a design operating point.

A ‘cycle of concentration’ measures the degree to which the solid impurities in the makeup water are concentrated in the recirculating water of an evaporative system. The higher this ratio, the more the impurities in the makeup water are being concentrated in the system water. Put simply, this specifies how often fresh water added can be used or recirculated before it needs to be drained.

Drain rates lower than this critical value save water, but result in harmful mineral buildup and cause premature servicing or replacement of parts. Conversely, when loads and conditions are milder than the design point, a lot of water is wasted as it is sent to drain before it has gone through its full cycle, decreasing the overall efficiency of the unit.

How do Seeley International evaporative coolers reduce water wastage?

Seeley International’s Braemar and Breezair products solve the water drain rate problem by continuously monitoring water quality in the unit so that the cycle is always optimised to both operating conditions and hardness level in the local feed water. This is achieved by using sump water conductivity as an indicator of mineral concentration. The systems have two conductivity setpoints, a high setting for soft water locations to save water with higher cycles of concentration, and a low setting for hard water areas to be sure the cooler is protected from mineral buildup.

When the cooler reaches its limit of mineral concentration, it automatically drains the water.

The drain water on Seeley International evaporative coolers is, therefore, not excess or wastage; it is protective.

Seeley International’s active water management system uses half the water of typical bleed approaches found in other or older evaporative cooler technologies. If a constant bleed system is used to reach the same CoC as Seeley in a hard water environment, a less sophisticated cooler could easily use over 3 times the water that a Seeley product does, meeting the same load. Even if the lower quality cooler adopts a strategy of underwatering and replacing its damaged media every year or two, Seeley International coolers will use half the water whilst preserving their evaporative heat exchangers.

On a servicing level, this means the conductivity sensor must be maintained on a regular basis to ensure accurate readings and water drainage. Hard water locations may warrant more frequent attention.

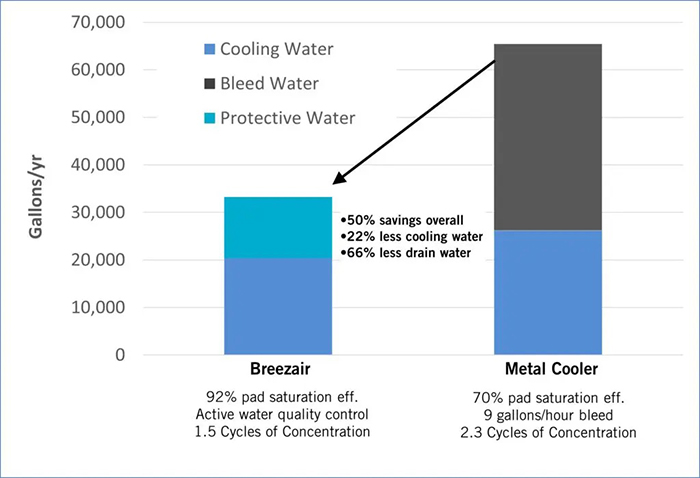

Compare the water usage of a Seeley International Breezair evaporative cooler versus a traditional metal cooler.

Note: Analysis based on low setting for hardwater application. Litre equivalent for Breezair equals 125,872l Vs metal cooler’s 247,629l.

Water is the most important resource on earth. On an individual, community, national and international level, we must take a proactive approach to preserve water resources, mitigate the risk of water scarcity, maintain public health and support economic growth.