Leading Australian steel building products company, Lysaght is celebrating an impressive milestone this year, having completed 100 years of local manufacturing.

While the current Lysaght range covers roofing and walling, architectural cladding, guttering, fascia and rainwater goods, fencing and screening, steel sections, formwork and framing, patios, carports and structures, it’s undoubtedly corrugated iron that drives the company’s reputation in the building industry. This steel building product has been used on everything from the roofs and bull-nose verandas of heritage homes, through to shearing sheds and outback dunnies, and more recently in en vogue architectural building projects.

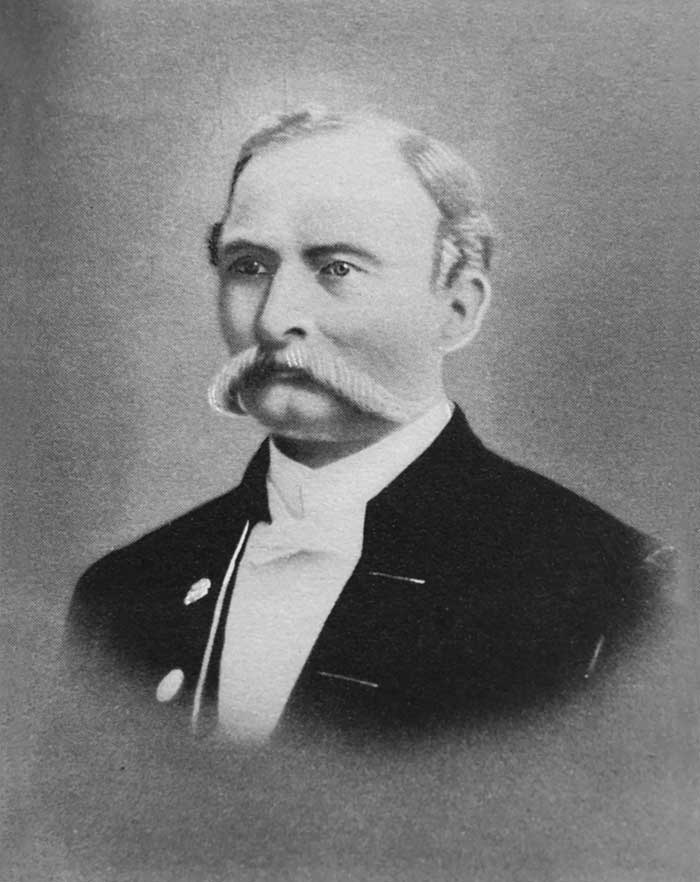

The product’s journey to national icon status can be traced back to Britain, where entrepreneurial Irishman John Lysaght began galvanising corrugated steel sheeting in Bristol during 1857. He registered the product under the trademark ‘ORB’, which continues to be used to this day.

After satisfying demand in the United Kingdom, which was being fuelled by the Industrial Revolution, Lysaght turned his attention to export markets, namely Australia, where he saw huge opportunities arising from the gold rush of the late 1800s. He began exporting to the colony soon afterwards.

After selling ORB in Australia through independent merchants, Lysaght established his own distribution company, the ‘Victorian Galvanised Iron and Wire Company’, which acted as a central selling agency. The venture worked well and by 1913, some 80,000 tonnes of ORB had been shipped to Australia.

World War I saw compulsory redirection of production capacity to assist the war effort, devastating local supply and highlighting the need for a local production presence in Australia.

Within three months of the war commencing, the company (now under the direction of John Lysaght’s nephew Herbert Royse Lysaght in Australia) was making arrangements to purchase 24 acres of land in Newcastle, NSW adjacent to a site already owned by Broken Hill Pty. Co. (BHP).

John Lysaght (Australia) Pty Ltd was formed the following year in 1917 with the intent of establishing a manufacturing site in Australia. Approximately four years later in April 1921, the new Lysaght company commenced manufacturing at its purpose-built site in Newcastle.

Thus began the Australian-made journey of the popular ORB corrugated profile; 100 years on, the company continues on its path of innovation and success.

Lysaght general manager, Peta Renkin said the company was extremely proud of reaching the important milestone.

“For Lysaght to have reached 100 years of manufacturing in Australia is an extremely satisfying achievement for our company,” Renkin said.

“It’s proof that there’s viability in local production – Lysaght has worked hard to develop new product lines, to innovate and to make manufacturing processes as efficient as possible while still providing premium quality products and offering superior support.

“Of course, this achievement would not have been possible without the dedication of Lysaght employees and the ongoing support of our business partners and clients, so to all of you we say ‘thank you’ and we look forward to the future.”

Today, Lysaght’s parent company, BlueScope, supplies it with Australia-made steel, with manufacturing (customising, forming and profiling) of the Lysaght products overseen by skilled production technicians at over 40 Lysaght branches nationwide.

Along with products such as CUSTOM ORB – whose heritage can be traced back to ORB – Lysaght has continued to innovate and lead the industry, introducing many game-changing products to market including KLIP-LOK and BONDEK.

KLIP-LOK

KLIP-LOK was launched in the 1970s to allow commercial building designers to develop roof systems that offered larger water carrying capacity and concealed fixing to help the weather resistance of these larger structures. It also allowed roof structures with gentler slopes, while providing excellent water carrying capacity and fewer joins because of its longer length.

The evolution continued with KLIP-LOK 700 in the 1990s, with the introduction of a wider profile consistent with the higher volume profiles of CUSTOM ORB, which increased manufacturing efficiencies.

The current profile, KLIP LOK 700 HI- STRENGTH improved sheet strength and water capacity while providing longer sheet lengths. The introduction of a new clipping system, LOK-KLIP also solved problems caused by sheet lapping.

A major leap in roof design and integrity was then achieved by rolling the KLIP-LOK profile on site and ‘straight-to-roof’, which allowed roof sheet lengths of up to 100m, thereby eliminating joins.

BONDEK

BONDEK was introduced in the 1960s as a permanent formwork system to replace timber. It provided savings in reinforcement requirements as the BONDEK system formed part of the steel reinforcement and also assisted fire ratings.

In the late 1980s, a quantum leap was achieved with the introduction of BONDEK II. The new design dramatically improved the interaction between steel and concrete, resulting in further reductions in steel reinforcing requirements and further improved fire ratings. The latest advancement to the range is BONDEK PLUS, which provides greater spanning capabilities.

Lysaght Product Innovation Group

All Lysaght product breakthroughs and enhancements are made possible through the work of the Product Innovation Group, a team of dedicated engineers responsible for bringing ideas to life, and ensuring all products meet Australian standards and equally importantly, the lofty standards of parent company BlueScope.

Using its NATA-accredited testing facility, the Product Innovation Group is able to undertake critical bespoke product development tasks including prototyping, product development, building system design, global and Australian standards compliance testing, cyclonic testing conditions, design software development and installation and usage guides.