University of Sydney’s civil engineering researchers are set to release a design process for steel structures in Australia that will guide safe, reliable, and cost effective steel construction in one simple, computer-aided step.

Structural reliability expert Dr Hao Zhang says that a team of researches has completed a four-year project that analysed steel structures used in the Australian construction industry, and following up with a reassessment of Australia’s steel structural modes.

“In the project we shifted the focus of design from the individual components and its connection strengths to the overall structural behaviour and strength of the entire system,” says Dr Zhang, senior lecturer in the School of Civil Engineering, and co-investigator on the project.

“The component-based design approach can overestimate the load carrying capacity of structural systems, causing unsafe designs.”

The structural analysis process developed by the University’s team combines examination, evaluation and capacity checking into a single step. Their research of the past four years has also highlighted failures within the system currently used.

“The core of this project has been a rigorous statistical assessment of the system strength which considers structural redundancy, consequences of failure and statistical variations in loading and variables affecting the frame strength,” says Dr Zhang.

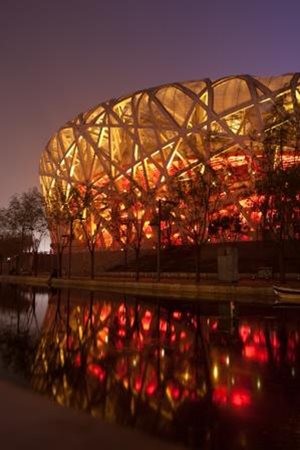

“The one-step process provides the opportunity to consider the consequences of failure during the design phase of the process. This is vital when designing any building including magnificent structures”

‘System reliability-based criteria’ is the name of the guidelines the team created for designing steel structures, and it advocates the guidelines to all those considering designing with the material.

“The aim is to make design-by-analysis the chosen method for designing steel structures. Current procedures rely on hundreds of equations stipulated in national codes for calculating the strength of individual components of structural frames, like columns and beams. These procedures will become obsolete when designing by analysis, as member strengths are implicitly checked,” notes Professor Kim Rasmussen, head of the School of Civil Engineering

“The one-step process provides the opportunity to consider the consequences of failure during the design phase of the process. This is vital when designing any building including magnificent structures such as Beijing’s Bird Nest (Below) or National Grand Theatre (Above),” says Dr Zhang.

Professor Rasmussen also highlighted the researcher innovations and says it is important to change the model of steel structural design immediately.

Professor Rasmussen also highlighted the researcher innovations and says it is important to change the model of steel structural design immediately.

“What is important is the strength and weight of materials used to design reliable steel frames.”

“However, the veracity of the structural components and the parts that connect them as a whole are the hidden key.”

He highlights the new one-step process as effective in giving Australian businesses the competitive edge on the international market.

"Outcomes of this project will help Australian structural design firms and engineers to be at the forefront of design methodology. It also can assist Australian companies competing in South East Asia, Middle East and European markets,” he says.

“We envisage that over time our one-step methodology will be adopted throughout the world.”

The research team consisted of:

Professor Kim Rasmussen, University of Sydney

Dr Hao Zhang, University of Sydney

Five PhD students, University of Sydney

Professor Bruce Ellingwood, Georgia Institute of Technology, Atlanta

Visit http://sydney.edu.au/engineering/civil/research/case/projects/reliability.shtml for more information.