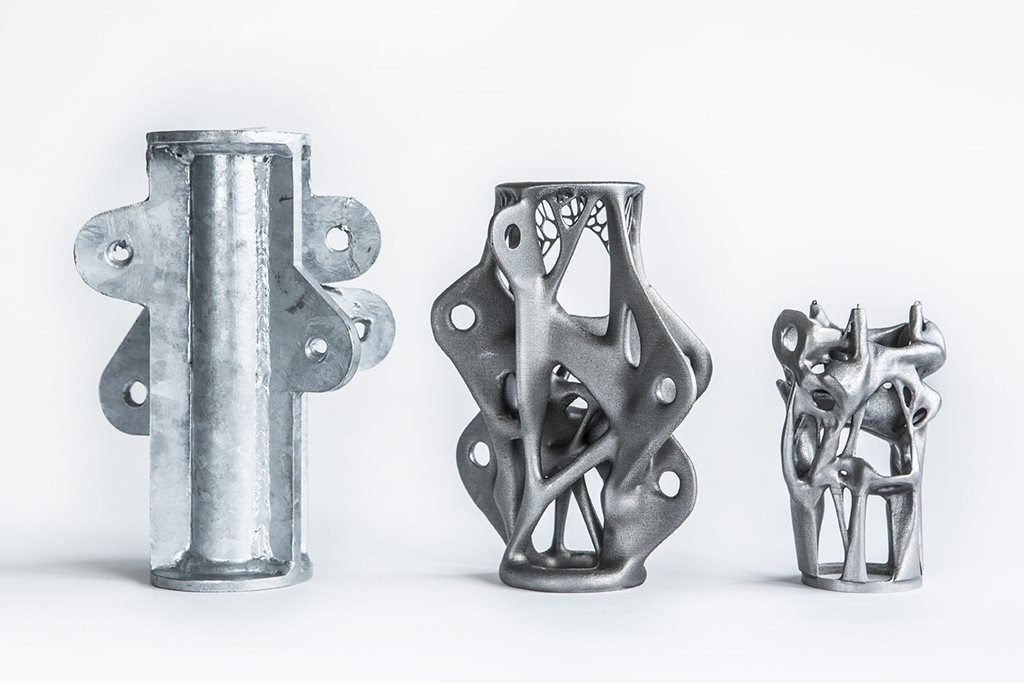

A series of photographs released by Arup engineers in Amsterdam could reveal the future potential of 3D printing in the construction and manufacturing sectors.

The photographs show three structural elements that are designed to carry the same structural loads and forces. The difference between them is that one of the elements has been manufactured using a newly honed version of the additive approach—more commonly known as 3D printing—and as a result is approximately half the size of a traditionally produced structural node and a quarter of the weight.

Arup claims that this technology can enhance the design and production process to the point that the weight and resulting cost of future construction materials could be reduced significantly.

The height of the smallest structural node on the right of the picture is approximately half of the traditionally produced piece on the left. This creates a direct weight reduction per node of 75 per cent and implies a weight reduction of the total structure of more than 40 per cent, according to the design team.

The height of the smallest structural node on the right of the picture is approximately half of the traditionally produced piece on the left. This creates a direct weight reduction per node of 75 per cent and implies a weight reduction of the total structure of more than 40 per cent, according to the design team.

“The additive manufacturing approach means that manufacturers can create highly complex, individually designed pieces and print them directly in metal,” says Arup.

“This in itself has tremendous implications for reducing costs and cutting waste. But the latest advances in the design techniques…mean that far smaller, lighter elements can deliver the same function and strength as those created by traditional methods.”

Related: smartNodes: exploring 3D printing possibilities in the building industry

Related: Could architectural 3D printing usher a comeback for physical models?

Arup Team Leader Salomé Galjaard says that having smaller, lighter structural nodes also has broader implications for a project.

“On a construction project that means we could be looking at an overall weight reduction of the total structure of more than 40 per cent,” he says.

“But the really exciting part is that this technique can potentially be applied to any industry that uses complex, high quality, metal products.”

Arup has been working with software company Altair to explore the latest software tools.

Images: Supplied