Group numbers, also called Fire Group numbers or Material Group numbers, are a requirement of the BCA/ NCC 2019, for all internal linings of commercial buildings in Australia.

This requirement is listed in Part C1.10 and Specification C1.10 of the National Construction Code 2019, and references AS5637.1 as the Australian Standard that will determine the Fire Group number of any wall or ceiling lining or lining system.

(These groups are also referred to as BCA Group Ratings or Fire Rating Group numbers.)

This specification explains what parts of a building are required to be Group 1, 2 or 3 Fire Rating. A Group 4 Fire Rating, which is another possible outcome of the testing systems, cannot be used in commercial buildings (Types 2 to 9 buildings).

Note that you can use a lower Group number than what is specified; for example, if Fire Group 3 is required, you can also use Fire Group 1 or Fire Group 2.

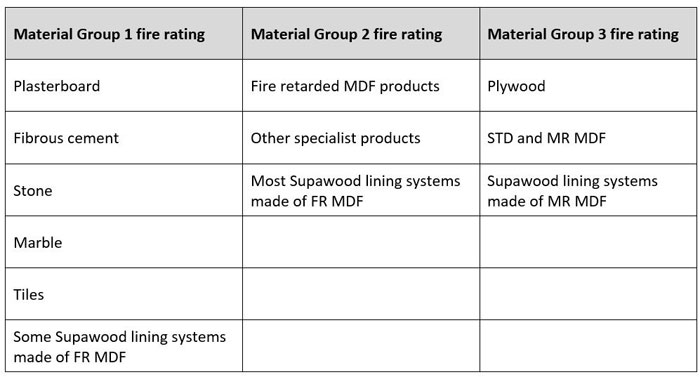

Here is a list of some typical materials with their Group numbers:

Two types of fire tests are allowed under AS5637.1, depending on the lining system being used. These two tests and the rules regarding them are explained below:

AS3837

This test is a Cone Calorimeter test, which involves heating a 100x100mm sample for 20 minutes and measuring the heat and smoke given off in combustion. As it is a small scale test, linings that would react differently in a full room test situation are not allowed under this test. Most timber products are allowed under this test but not Fire Retarded MDF. Products with gaps, joints or openings are not allowed. Also not allowed are products that shrink and melt away from the flame and products made from different types of laminates joined together, like ACP.

(Note that New Zealand uses a similar test to AS3837 but it is run for 30 minutes and is called ISO5660).

ISO9705

This is a full room burn test, and involves lining three walls and the ceiling of the test room with the lining product. The framing and fixing system used in this test should replicate what is used in construction as far as possible, but this is not always done, thus affecting the result in favour of the supplier. These test reports need to be checked carefully to ensure they match what is being supplied for the project. All Supawood fire testing has been done to match the likely fixing scenario you will have on site, regardless of how this may affect the outcome of the fire test.

Based on the outcome of these tests, a material or lining system will be certified as Group 1, 2 or 3. Specification C1.10 then describes in detail what Material Group number is required in what area.

For example, enclosed fire escapes are required to be Material Group 1.

Generally Material Group 3 is acceptable in most areas.

The rules listed to determine what Fire Group is acceptable in what area can be quite difficult and ambiguous to follow, so we have published a ‘cheat sheet’ to make this easier for you.

Download our Cheat Sheet

The interpretation of the building surveyor on your project is the final authority, so you will need to have any interpretation confirmed by your building surveyor.

Finally, remember that Supawood is here to help you. If you are unsure about anything, feel free to contact us and we will be glad to clarify your situation for you.

Julian Beattie | Director - Human Resources & Innovation